Furnace Tube Welding

Innovative furnace tube welding improves u-bend weld mechanical and chemical properties

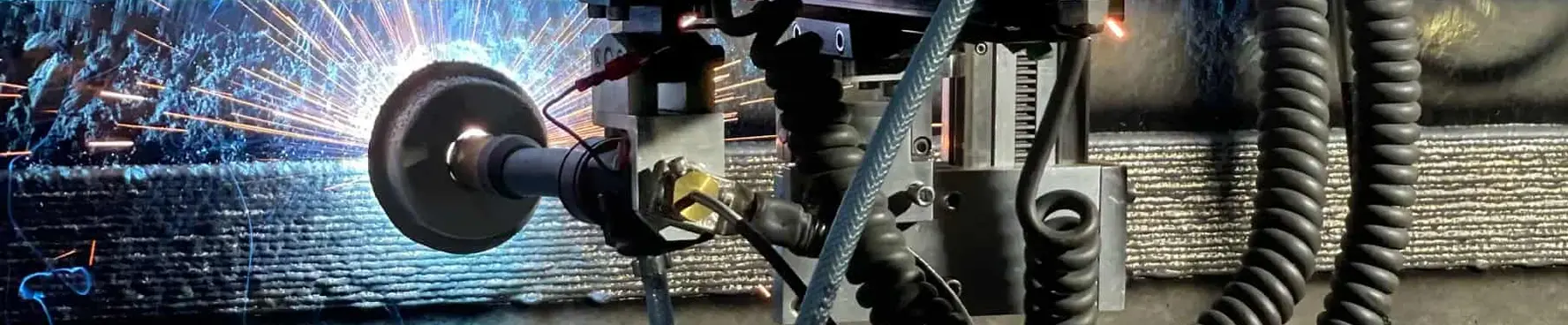

WSI’s specialty welding solutions are designed to overcome the specific challenges of U-bend welds in heaters and furnaces, providing refineries with reliable, high-quality welds that support their maintenance and upgrade goals. By utilizing our revolutionary HotPulse®-enabled orbital welding equipment, we deliver exceptionally high-quality GTAW (Gas Tungsten Arc Welding) welds that withstand the rigorous demands of refinery operations.

HotPulse-enabled welding technology for superior furnace tube welding results

Product heaters and furnaces are crucial in refineries, and many refiners upgrade their metallurgy to reduce degradation and maintenance costs. These upgrades often require numerous insitu orbital welds, which are challenging due to high preheat requirements and complex geometries, leading to significant weld failures.

To address these challenges, WSI developed HotPulse orbital welding technology, or HP GTAW™ welding, specifically for difficult U-bend welds. The equipment positions the operator safely away from high preheat discomfort, while HotPulse technology delivers exceptionally high-quality GTAW (Gas Tungsten Arc Welding) welds at high production rates. This makes it ideal for various applications, including reformer furnace tube replacement, reformer furnace repair and maintenance, and general furnace tube replacement.

Enhanced welding with advanced materials for critical refinery components

Using advanced materials like 9CrV (Chromium-Vanadium Steel), our HotPulse technology significantly enhances the mechanical and chemical properties of welds compared to conventional methods. This improves the integrity and longevity of the welds and ensures the welding process meets stringent quality standards and adheres to tight schedules.

Contact Us

DOWNLOADS

Locations

Follow WSI

Related Feature Stories

WSI’s Unifuse™ Technology for EAF Duct Life Extension

Unifuse Alloy 625 Weld Metal Overlay is changing the paradigm on how the industry will view Electric Arc Furnace water-cooled ducts and BOF water-cooled hoods.

Machine Welding for Steam Methane Reformer Furnace Catalyst Tubes with Clearance Challenges

WSI maintains a variety of engineered repair solutions to condense schedule, eliminate manpower in congested work areas and achieve first time quality.

Coke Drum Services

Industry leading life extension and repair processes to address low cycle fatigue failure

Piping Services

Piping services with revolutionary machine orbital welding for planned or emergent outages

Superheater, Reheater, and Economizer Services

Over 30 years of experience in superheater, reheater, and economizer services

Waterwall Services

World’s largest installed base for the mitigation of fireside corrosion